Emergency Relief System Design Using Diers Technology Pdf

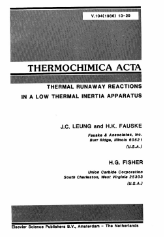

Per the AIChE, "The Design Institute for Emergency Relief Systems (DIERS) was formed in 1976 as a consortium of 29 companies to develop methods for the design of emergency relief systems to handle runaway reactions. DIERS SPENT $1.6 million to investigate the two-phase vapor-liquid onset/disengagement dynamics and the hydrodynamics of emergency relief systems. Of particular interest to DIERS were the prediction of two-phase flow venting and the applicability of various sizing methods for two-phase vapor-liquid flashing flow. DIERS became a Users Group in 1985 with over 200 companies (75 percent domestic and 25 percent international) ultimately requesting membership and having their corporate representatives participate in the semi-annual meetings. Hans K. Fauske, Fauske & Associates, LLC, the "Grandfather" of DIERS Fauske & Associates, LLC (FAI) was the principal research contractor for the Design Institute for Emergency Relief Systems (DIERS), an extensive R & D program sponsored by those 29 companies under the auspices of AIChE and completed in 1985. Company founder, Dr. Hans K. Fauske served as the principal investigator and overall technical leader of the DIERS research project. A primary purpose of that effort was the evaluation of emergency relief vent requirements, including energy and gas release rates for systems under upset conditions and the effect of two-phase flow on the emergency discharge process. The DIERS program resulted in the development of a bench-scale low thermal inertia adiabatic calorimeter, which was first commercialized as the Vent Sizing Package (VSP2™). Later improvements led to the VSP2™. The Reactive System Screening Tool (RSST™) was introduced by FAI in 1989 to provide an easy, inexpensive approach to the DIERS testing method. Recent enhancements led to the Advanced RSST (ARSST™) in 1999. FAI uses the DIERS-based VSP2™ and ARSST™ calorimeters to characterize chemical systems and design emergency pressure relief systems. Both instruments provide vent sizing data that are directly applicable to the process scale. Dr. Fauske provided overall technical direction for the AIChE's acclaimed DIERS program formed to develop methods for the design of emergency relief systems to handle runaway reactions. Currently, Dr. Fauske is performing a pivotal role in resolving potential process safety issues and the development of inherently safe nuclear and chemical process reactor concepts. Published in 1986 by Elsevier Thermochimica Acta, "Thermal Runaway Reactions In a Low Thermal Inertia Apparatus" by Dr. J.C. Leung and Dr. H.K. Fauske of Fauske & Associates, LLC along with Dr. Harold Fisher of Union Carbide Corporation, as shown below states: "A new apparatus utilizing a unique low heat capacity sample container is described for studying thermal runaway reactions. Other features provided by this new technique include nearly equal pressures between the sample container and the outside containment vessel as the runaway proceeds, a nearly zero temperature gradient outside the sample container to minimize heat loss, a magnetic stirring mechanism, and a remote feed capability. Thermal data obtained for styrene polymerization and di-t-butyl peroxide decomposition were shown to be in excellent agreement with previously published kinetic models. Finally, a base-catalyzed phenol-formaldehyde reaction in a runaway situation is presented." Here, in the intro, two devices commonly used to obtain information on the exothermicity of runaway reaction are the differential scanning calorimeter (DSC) and the accelerating rate calorimeter (ARC) are introduced. Dr.'s Joseph C. Leung and Fauske of Fauske & Associates, LLC extended the applications further in "Runaway Systems Characterization and Vent Sizing Based on DIERS Methodology." Looking beyond trends, the article discusses the diverse nature of runaway systems. Vent sizing for 50 industrial chemical systems testing over 2 years. Please see more here: Dr. Fauske wrote: Emergency Relief System Design for Reactive and Non-Reactive Systems: Extension of the DIERS Methodology."In it, he states: "Simple mechanistic models for reactive and non-reactive chemicals are summarized. The DIERS methodology has been extended as well as simplified to account for vapor disengagement and frictional effects, including laminar flow conditions-both principal objectives of the DIERS program." He further points out that while two-phase flow phenomena in connection with relief system design for runaway chemical reactions were recognized in past research and computerized modeling by Boyle and Huff, a database is seldom available due to provide vent sizing due to the need for extensive thermokinetic and thermophysical characterizations of the reacting systems. Thus, less complicated analytical methods allowing vent sizing from direct test data such as the DIERS bench-scale apparatus is preferred. For the first time, runaway reactions in the DIERS can approximate the severity of those in industrial vessels. "the simplified models together with the bench-scale equipment is now commercially available under the trademark VSP (Vent Sizing Package)…" "An Easy, Inexpensive Approach to the DIERS Procedure," Michael J. Creed and Dr. Fauske, both of Fauske & Associates, LLC published the article below stating, "The DIERS program included two key contributions. One was emphasizing the importance of correctly determining the source term energy-release and gas-generation rates for vapor and gassy systems, respectively) under upset conditions and the development of a new bench-scale apparatus with which such a determination can be obtained and extrapolated directly to full-scale application. The other was emphasizing the importance of two-phase flow in the emergency-relief discharge process and the development of vent-sizing techniques that are valid for multiphase behavior. It has been suggested, however, that the DIERS methodology can be so complex and time consuming that it may be beyond the capability of the small facility operator and, therefore, hat much more user-friendly techniques must be developed. Hopefully, the inexpensive and easy-to-use methodology summarized here will satisfy this need and encourage the widespread use of the AIChE-IDERS vent-sizing methodology." In the Winter 2019 Issue of FAI's Process Safety News, Dr. Fauske teased "Clarification of Non-Equilibrium and Equilibrium Flashing Flows: A simple and easy to apply two-phase flow model that is in excellent agreement with safety valve, and nozzle-tube data is illustrated below. The constant flow area length L is the key parameter and values leading to non-equilibrium (short) and equilibrium (long) flashing flows are provided by the flow model. The nozzle inlet condition can be a subcooled liquid, a saturated liquid or low quality two-phase vapor-liquid mixture, all conditions predicted accurately by the simple flow model. The details and simple model example calculations will be presented at the AIChE DIERS September 16-18, 2019 meeting in Burr Ridge, Illinois, by Hans K. Fauske, D.Sc. Emeritus President and Regent Advisor, Fauske & Associates, LLC." Fauske & Associates, LLC proudly provides training and regularly published articles and blogs on these topics. The popular Relief System Design Course provides CEUs and is generally taught over two days. Unlike other emergency vent sizing course, this curriculum highlight simplified calculation methods capable of giving safe – but not overly conservative relief system designs, with an emphasis on reactive chemistries and the role of two-phase flow. Benchmarking of these methods will be illustrated with incidents and available plant data. Utilization of methods and equations is demonstrated through practical design examples, covering vapor, gassy, and hybrid systems. Attendees will participate in group workshops and complete an independent quiz at the end of the course to ensure comprehension of the material. A laboratory session demonstration of experimental techniques is included. For more information about a Relief System Design Course, The ARSST™ enables users to quickly obtain reliable adiabatic data which can be used for a variety of safety applications including characterization of material compatibility, thermal stability, and reaction chemistry. Test data includes adiabatic rates of temperature and pressure change which, due to the low thermal inertia, can be directly applied to process scale to determine relief vent sizes, quench tank designs and other relief system design parameters related to process safety management. Fauske & Associates, LLC's (FAI) Vent Sizing Package 2™ (VSP2™) is a low thermal inertia adiabatic calorimeter used for process hazard characterization that utilizes state-of-the-art DIERS technology to obtain critical upset process design data. It is the commercial version of the original DIERS bench-scale apparatus. At FAI, we not only utilize the VSP2™ in our fully equipped hazards laboratory, but we also manufacture and sell the calorimeter for use by our clients. Its versatile and innovative design allows the VSP2™ to simulate upset (abnormal) conditions which might lead to a runaway chemical reaction (e.g., loss of cooling, loss of stirring, mischarge of reagents, mass-loaded upset, batch contamination, fire exposure heating, etc.). Resulting temperature and pressure rise rates are directly scalable since it is a low thermal inertia (phi-factor) apparatus. The VSP2™ utilizes established DIERS technology to identify and quantify process safety hazards so they can be prevented or accommodated by process design. Test data includes adiabatic rates of temperature and pressure change which, due to the low thermal inertia, can be directly applied to process scale to determine relief vent sizes, quench tank designs and other relief system design parameters related to process safety management. Adiabatic data obtained with the VSP2™ can be used to characterize reactive chemical and consequences that could occur due to process upset conditions. The versatile configurations offered by the VSP2™ design directly simulate process conditions including: Use of the VSP2™ can help users obtain complete chemical system data such as: FAI has also created the FERST software to allow users to implement practical emergency vent sizing using industry-recognized methodology. It applies DIERS methodology (including the Leung-Omega and Fauske methods) for reactive chemistry and API 520/2000 or NFPA 30 for non-reactive systems. Gabe Wood, Manager of Thermal Hazards Testing & Consulting at FAI, recently presented "Using the VSP2™ to Perform Relief Sizing on Epichlorohydrin Chemistry" to the DIERS User Group Meeting in Germany. Here is a video as he explains the presentation to us:

table of Contents

The Purpose of DIERS

Technical Background

In the April 1987 Plant/Operations Progress issue,

Published in Plant /Operations Progress (July 1988)

In 1990, "An Easy, Inexpensive Approach to the DIERS Procedure"

Many white papers, articles, and blogs have been written by Fauske & Associates, LLC since 1980 about relief system design, runaway reactions, the ARSST™, the VSP2™, DIERS, two-phase flow and more. Here are a few:

Relief System Design Training

Course Topics – Day 1

Course Topics – Day 2

Course Topics – Day 3

Learning Outcomes

contact FAIUniversity@fauske.com or click here:

Benefits

Features

Applications

Vent Sizing Package 2 (VSP2™) Background

Benefits

Features

Applications

Topics: vent sizing, ARSST, VSP2, DIERS, emergency relief vent, PREvent, adiabatic calorimeter

Emergency Relief System Design Using Diers Technology Pdf

Source: https://www.fauske.com/blog/emergency-relief-system-design-using-diers-technology